Engineers from Novosibirsk State Technical University (NETI) have developed a unique prototype of equipment for monitoring the parameters of capacitors at various stages of their production, according to a special order from the OXIDE plant.

Electrical capacitors are one of the main elements of the electronic component base (ECB) of radio electronics. It is impossible to manufacture any electronic device without capacitors. Currently, the key problem of domestic instrument engineering is dependence on foreign—made electronic devices. Therefore, the modernization of production facilities, an increase in production volumes and the development of new ECB products are the primary tasks of the electronic industry enterprises.

During the modernization of the production of K-53 series capacitors at the OXIDE plant, it was necessary to create a unified automated process control system (ACS). One of the elements of this system is a set of equipment for monitoring the parameters of capacitors during their production and testing.

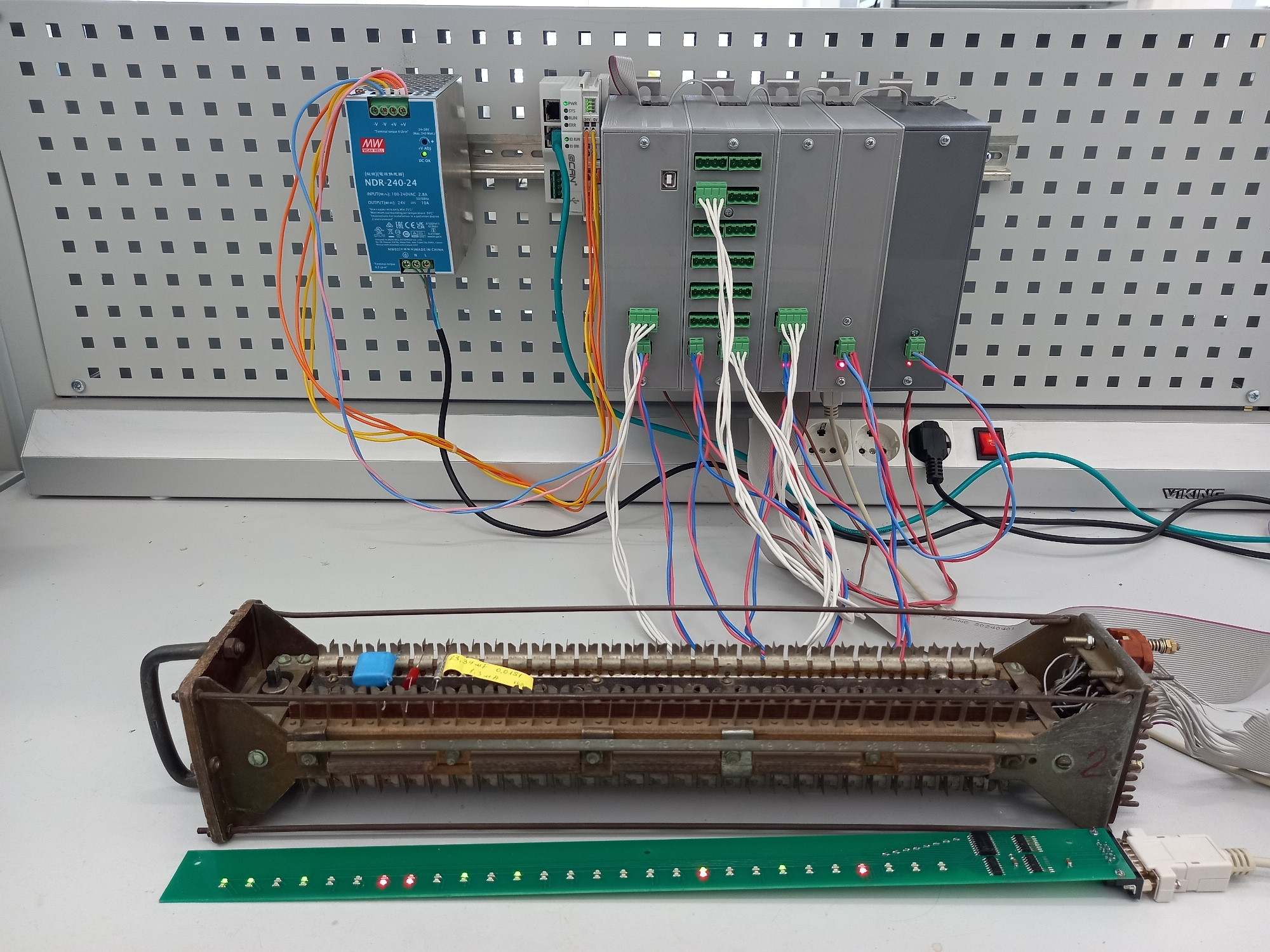

Specialists from the Scientific Research Laboratory of Experimental Technology (SRL TE), the Engineering and Production Center for Electronics, Electrical Engineering and Energy of NSTU-NETI, has created a prototype of equipment in the form of specially designed modules controlled via the internal data exchange bus of the programmable logic controller (PLC) GCAN PLC-510.

5 modules have been developed: a capacitor parameter meter, a switch of measuring cells, a switch of elements, a source of controlled polarization voltage (CPV), an indicator of rejected capacitors.

The capacitor parameter meter allows you to record the following parameters: electrical capacity at a frequency of 50 Hz, loss angle tangent and leakage current. All measurements are carried out at the polarization voltage, which is set by the IPN on command from the PLC. The capacitors in the measuring cells are alternately connected to the measuring unit by means of a switch of elements, also on command from the PLC. Up to 56 capacitors can be installed in one cell. If testing is performed simultaneously from several cells, then a switch is used. Information about the non-tested capacitors is displayed using the rejection indicator module.

Such a set of modules will make it possible to assemble two automated workstations: a station for loading and unloading capacitors into test cassettes and a thermal stability testing facility. Workstations using PLC facilities will be integrated into a single network for remote data exchange with the server. A PLC-compatible SCADA system will be installed on the server.

In case of failure of one of the modules, a quick hot swap with a similar one is possible without disconnecting power from the PLC. This eliminates data loss and process shutdown.

As noted by Arseniy Morozov, Candidate of Technical Sciences, head of the Experimental Engineering Research Laboratory, the main advantages of the developed prototype test equipment are the combined use of standard GCANPLC-510 PLC peripherals with measuring and I/O modules specially developed in the laboratory. Any PLC, including GCAN, has at its disposal a wide range of software for hardware programming and creation of SCADA systems. Nevertheless, a set of standard I/O modules for PLCs is designed for control system design and is completely unsuitable for creating complex measuring systems. The engineers from NSTU-NETI managed to develop the measuring modules necessary for the implementation of this project, compatible with the GCAN PLC-510 PLC. This approach will make it possible to create any test equipment and software for it in the shortest possible time.

The development of the test equipment was carried out with the involvement of students from the design bureau, which allowed them to acquire practical skills in the design, configuration and operation of measuring equipment. Based on the results of the work, one graduation project was completed. This contributes to the training of qualified personnel for the domestic electronics industry.

Other developments of SRL TE NSTU-NETI can be found on the laboratory's website.