Novosibirsk State Technical University in cooperation with Novosibirsk Ya.L.Tsyvian Research Institute of Traumatology and Orthopedics medical and technological center "Medical Technology Park", the Institute of solid state chemistry and Mechanochemistry of SB RAS and ZAO "NEVZ-Keramiks" have developed the nanoceramic hip prosthesis.

At the moment, more than 3000 (three thousand) patients received hip prostheses;

- Method of producing welded joints of dissimilar metallic materials (Patent RU 2470755)

- Method of producing tungsten oxide nanotubes (Patent RU 2451577)

The technical solutions are protected with 18 patents of the Russian Federation.The most significant scientific and applied results include: research group have developed original laboratory research installations such as installation for the study of cyclic crack resistance to determine materials microplasticity; the installation for the study of contact endurance of the hardened products; the installation for the study of the materials wear process in gas-abrasive environment; installation for the study of the materials wear process in conditions of friction on loosely attached abrasive particles; die-molds for ceramic materials molding; in-situ cell for combined structural and optoelectronic properties research of solar cells based on organic substrate.

Educational program 22.03.01 "Materials Science and Materials Technology" has obtained the international public accreditation and has been included into the register of educational programs accredited by Association for Engineering Education of Russia.

Structural strength theory

Structural strength theory of materials is based on the latest achievements in condensed matter physics, nonlinear fracture mechanics, theory of dislocations, and structural materials science integration. A new high technology, namely the controlled thermoplastic steel hardening (CTSH method), has been developed on the basis of the theory.

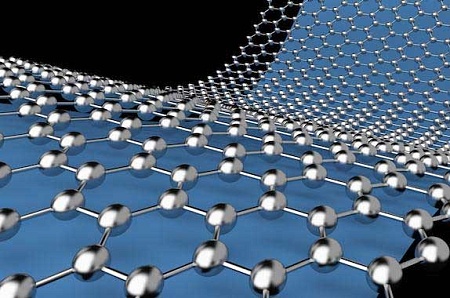

Nanoceramics

The addition of nanopowders allows increasing the density and, consequently, reducing the porosity of the produced ceramics. The optimal selection of the powder particle size after compaction and sintering has enabled the ceramics density to approach 100 percent of the theoretical density, which significantly increases ceramics strength. Over 960 articles have been published in the leading domestic and foreign journals, such as: «The Physics of Metals and Metallography», «Materials & Design», «Materials», «Solid Mechanics Engineering», «Metallurgical and Materials Transactions». A. Physical Metallurgy and Materials Science", "Journal of Solid State Chemistry", "Journal of Materials Science Research", "Russian Physics Bulletin" "Heavy Engineering", "Metallurgy and Heat Treatment of Metals", "Metal Working: Technology, Equipment, Tools", Physics of Metals and Metallography", "Physical Mesomechanics", "Chemistry for Sustainable Development", "Chemical Technology of Functional Materials", "Applied Mechanics and Materials", "Materials and Manufacturing Processes", "Metals and Materials International", "Science and Technology of Welding and Joining", "Surface Engineering", "Intermetallics", "Ceramics International", "Materials Chemistry and Physics", "Tool", "Steel", "Mechanical Engineering", "Thermophysics and Aeromechanics".

The core staff of the research group

- Tushinskiy Leonid Innokentievich

Doctor of Technical Sciences, Professor, Honored Science Worker of the Russian Federation, Emeritus Doctor of Silesian University of Technology, Emeritus Doctor of Prydniprovska State Academy of Civil Engineering and Architecture, Corresponding member of International Higher Education Academy of Sciences, Honored Worker of NSTU - Bataev Anatoly Andreevich

Rector of NSTU, Doctor of Technical Sciences, Professor, Full member of International Higher Education Academy of Sciences, laureate of the Novosibirskaya Oblast Government Prize for outstanding scientific achievements, Honored Worker of NSTU, Honored Worker of Higher Professional Education of the Russian Federation, Deputy Chairman of the dissertation Council D 212.173.13