Students of Novosibirsk State Technical University (NETI) assembled a "suitcase" — a data collection and control system for a burner device (BD). The student's development makes it possible to automate management and increase the efficiency and safety of burner devices at thermal power facilities.

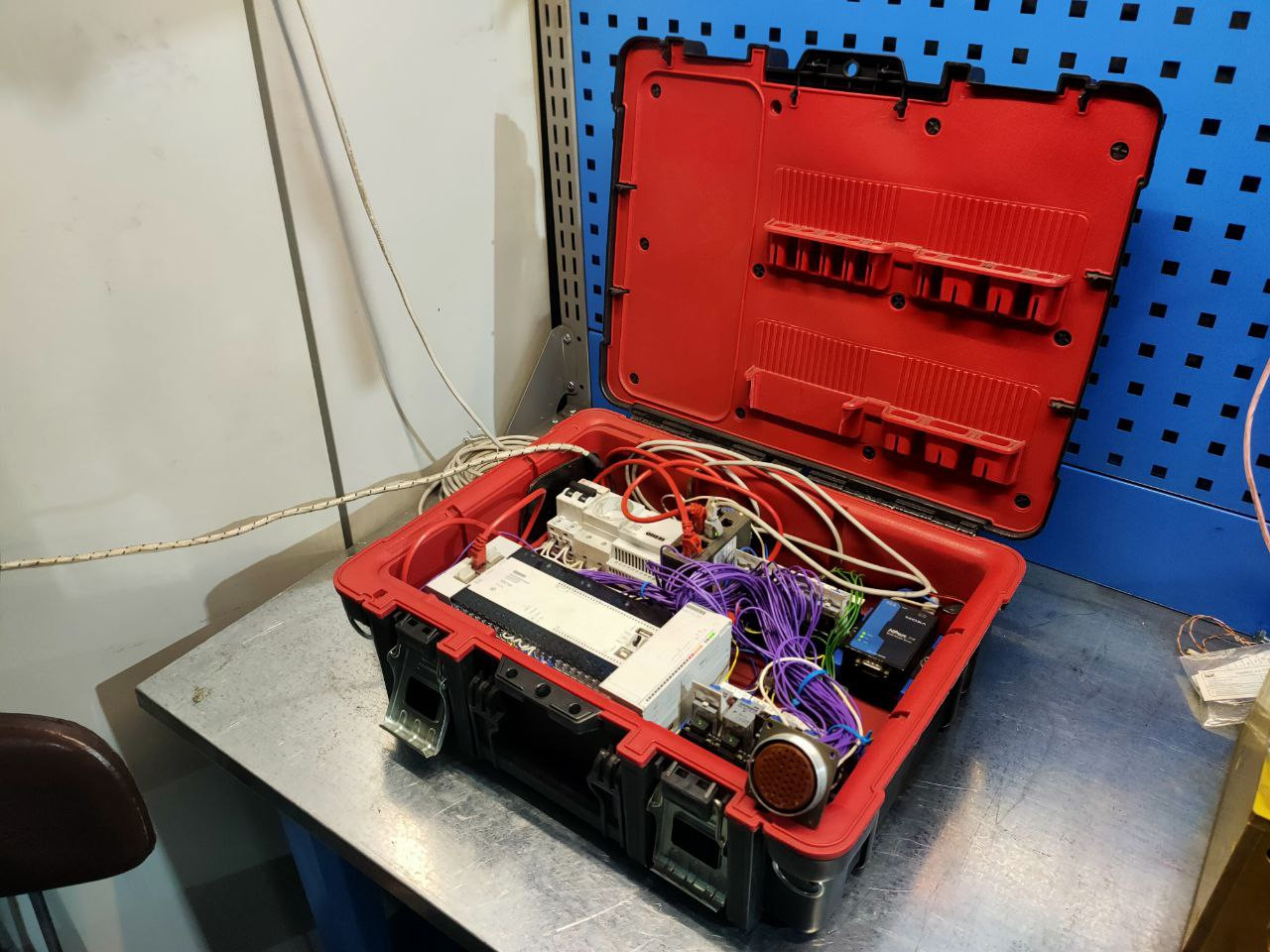

"The idea of creating a control system of this type arose after visiting one of the thermal power facilities, where the local monitoring and data collection system looked like a rather complex three-level network. This is a standard industrial scheme with high cost, massive dimensions, and a complete lack of mobility. Hence, the idea of creating a mobile "suitcase" was born. It is a housing in which various devices are installed — a programable logic controller (PLC), relays and other accessories. The "suitcase" is connected to all sensors and power systems, and signals pass through it, which enter the computer, where they are recorded. Sensor data and results can be displayed in the form of graphs and tables. We decided to make a unique device that is essentially universal for any burner, assembled a system from available components of domestic production and "rolled" it on the burner of the oil—free ignition system at the S. S. Kutateladze Institute of Thermophysics SB RAS," said Anton Pochtar, a graduate student at the Faculty of Energy of NSTU-NETI.

According to him, there are various control systems on the market that are designed for specific burner devices. The monitoring and data collection system designed by NSTU-NETI students, unlike its analogs, is universal and allows working with any burner device — gas, muffle, coal, and dual-fuel. For correct control of the control unit, it is necessary to know exactly the temperature at the characteristic points, fuel consumption, and air consumption. The cost of the prototype system at the moment is about 200 thousand rubles. Another advantage is that it is a convenient mobile device that can also be used during commissioning. This development may be of interest to companies producing heat and electricity to small stations where it is necessary to optimize the process of kindling or burning fuel.

"During the operation of burner devices running on solid and gaseous fuels, insufficient or excessive temperature of hot gasses can lead to inefficient operation of the system and excess fuel flow, low combustion efficiency — to large emissions and environmental problems. With the help of our development, it is possible to reduce fuel costs and improve environmental performance," added Anton Pochtar.

Currently, the development is at the stage of a working prototype. In the future it is planned to create a more functional "suitcase" that could process more signals, as well as add more capabilities to the system's functionality for controlling the control unit.